Common Myths and Misconceptions about Aluminium Powder Coating

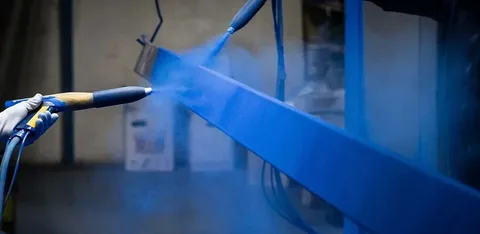

For industries and individuals alike, powder coating has become the popular choice for aluminium surfaces. Although myths and misconceptions exist, this durable and environmentally friendly process can be a source of confusion. In this article, we try to clarify these misunderstandings and show you through explanations, which can help you understand better aluminium powder coating if you are taking business within an aluminium powder coating company or aluminium extrusion profiles.

1. Myth: Powder coating is only for aesthetic purposes

Many people believe powder coating is applied to aluminium surfaces solely for its visual appeal. While aluminium extrusion profiles and other items do improve in appearance when powder coated, the benefits of powder coating do extend beyond aesthetic improvements. Robust protection against corrosion, weathering, and general wear is achieved with this coating method, making it the right choice for outdoor structures and all high-exposure applications. An aluminium powder coating company can alter the process to deliver the appropriate performance across different products so they’ll be more resistant to harsh conditions.

It also helps protect aluminium against fading, chipping, and scratching, thanks to powder coating. The durability of powder coating on alloys like aluminium enables it to be a top option in industries where durability and appearance matter.

2. Misconception: Powder coating is not environmentally friendly

Another myth that kept surfacing regarding powder coating is that it is harmful to the ecology or, put differently, cannot be recycled. In this regard, powder coating is believed to be one of the most eco-conscious options for coating. Unlike the traditional liquid paint that contains solvents, powder coating dispels a lesser amount of volatile organic compounds that are important in catalyzing the transformation of smog. It cuts down on air pollution and makes the process safer for aluminium extrusion profile workers in manufacturing facilities.

The powder used in the coating process is also reusable. Most aluminium powder coating companies use recycling systems to recycle overspray and unused powder for reuse, as opposed to disposal. It’s not only reducing waste but also reducing your overall material costs, and therefore, operating in a more sustainable process.

3. Myth: Powder coating cannot withstand harsh conditions

Some people assume that powder coating isn’t good enough to stand up to severe environmental conditions. Most likely, this misconception is a result of confusion about powder coating with other surface treatments. Aluminium is highly resistant to UV radiation, extreme temperatures, as well as weather elements and, therefore, a durable choice for indoor and outdoor applications alike.

Powder coating offers a reliable protective layer that is suitable in industries where aluminium extrusion profiles are subjected to heavy use or environmental stressors. Aluminium powder coating companies also provide coatings that are specifically applied and designed to withstand high abrasion levels, salt spray and chemicals, helping to further improve the durability of the aluminium. Powder-coated aluminium can find its way into architectural elements, automotive parts, or just about anything that can endure a wide range of conditions without compromising its integrity or appearance.

4. Misconception: Powder coating is only available in a few colours

One of the most common myths about powder coating is that it does not expand the colour options as traditional paint application methods can. In reality, aluminium powder coating companies offer a broad range of colours, finishes, and textures. This type of coating allows for a vast number of customization options that come in the form of matt, glossy, metallic, and textured finishes and primarily rely on customers’ preferences.

However, the diversity in colour and finish options is especially useful when you’re working with aluminium extrusion profiles for architectural or interior design projects. Powder coating companies also allow you to choose branding colours, natural elements, or other unique design needs without affecting functionality. Other than that, the ability to create custom colour formulations allows designers to get truly unique looks, from bold, bright hues to veiled, sophisticated tones. One of the other major benefits of powder coating is its versatility, which makes it the preferred choice for both decorative and practical applications without compromising its style and endurance.

5. Myth: Powder coating is not durable and wears off easily

One of the most enduring myths surrounding powder coating is that it is not durable and fades or wears off quickly. Powder coating is the most durable finish that one can get for any aluminium product. It is essentially electrostatically depositing a dry powder onto aluminium and then curing it under high temperatures to form a strong bond. The coating is cured and then fused to the aluminium, ensuring high resistance to peeling, chipping, and fading.

Powder coating holds more strength in aluminium extrusion profiles, particularly on the exterior, where it is continuously exposed to sunlight, moisture, and temperature fluctuations. Aluminium powder coatings companies rigorously test the coating to ensure that it will endure environmental factors in time, making it a dependable choice for aesthetics and durability.

6. Misconception: Powder coating is difficult to maintain

Some people made assertions about the belief that powder-coated aluminium requires long-term maintenance in its appearance and protection capability. This is another misconception; powder-coating requires little maintenance and upkeep. Unlike other coating styles that sometimes require reapplication at regular intervals or use certain speciality materials, powder-coated aluminium is extremely low in maintenance and cleanability.

Simple cleaning with mild soap and water is usually enough to keep aluminium extrusion profiles or powder-coated products for outdoor use looking new. Normally, an aluminium powder coating company would give clear instructions on how to care for their work, which typically includes not using abrasive cleaners and using a soft cloth or sponge. This will keep the surface scratch-free or damaged. Powder coating also creates a protective layer that is corrosion-resistant, fade-resistant, and resistant, which minimizes the time you need to spend touching up your piece. Following basic maintenance steps, powder-coated surfaces will keep their protective qualities and visual appeal for years, making them an excellent long-term investment.These myths and misconceptions usually do more damage than good for all the advantages that aluminium powder coating has to offer. In reality, powder coating gives an environmentally friendly, durable, customizable, and low-maintenance surface to aluminium in a broad array of aesthetic and functional applications. Consumers and businesses can get the look and durability they want for their aluminium extrusion profiles or other products without misconceptions when working with a reputable aluminium powder coating company.