How to Choose the Right Aluminium Profile for Electrical Safety

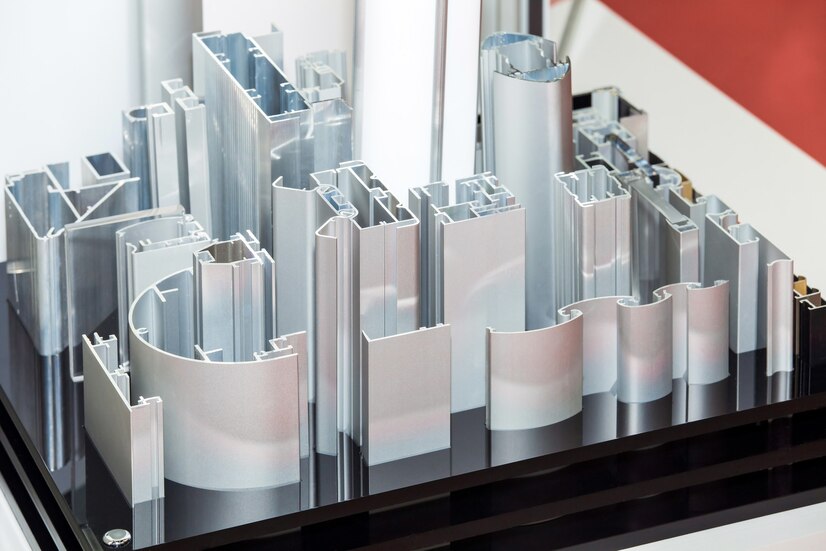

In today’s rapidly evolving industrial landscape, selecting the appropriate Aluminium extrusions Profiles for electrical applications has become increasingly crucial. Safety, efficiency, and reliability are paramount considerations when working with electrical systems, and the choice of proper aluminium components plays a vital role in achieving these objectives. Modern manufacturing processes have revolutionized how we approach electrical safety installations.

Understanding Aluminium Profiles in Electrical Applications

It is due to such high-quality aluminium profiles that massive utility ranges in the electrical safety sector have seen a revolution, primarily focusing on superior performance characteristics. The outstanding advantages offered by such components include excellent conductivity, robust corrosion resistance, and a remarkable strength-to-weight ratio. It is through these properties that they find diverse applications within the electrical industry, especially from simple enclosures to complex power distribution systems.

Material Quality Role

The type of selection of the material usage for electrical purposes necessitates a complete commitment to the standards and specifications. Quality-grade aluminium extrusion profiles have been envisaged under strict testing to ensure constant performance and reliability. Material composition, structural integrity, and manufacturing accuracy are all contributing factors in determining the suitability of the material for electrical applications, especially in safety-critical environments.

Design Consideration towards Electrical Safety

When creating electrical systems with aluminium profiles, there are many critical factors in the overall performance and safety. The overall effectiveness of the profile has to do with its geometry, material thickness, and surface finish. Engineers will have to consider not just the immediate requirements but also long-term performance characteristics when planning such installations for maximum safety and efficiency.

Thermal Management

Good dissipation of heat is necessary for electrical safety, and quality aluminium profiles occupy the first place when the feature of dissipation of heat is considered. A higher level of thermal conductivity ensures safe operating temperatures in various applications. Contemporary profile designs include sophisticated cooling features for efficient heat dissipation, including specific fin structures and improved surface areas.

Environmental Factors

The application of an electric environment in which aluminium profiles will be used is something that influences the right choice of High Quality Aluminium Profiles. Ambient temperature, humidity level, levels of chemicals, and atmospheric conditions require careful assessment. With excellent natural corrosion resistance, the aluminium is particularly suitable for this challenging environment, ensuring long-term reliability and safety.

Load-Bearing Requirements

Proper assessment of mechanical loads is an essential requirement in the selection of aluminium profiles for electrical applications. These comprise static and dynamic forces that may bear upon the installation. Factors to consider include the weight of equipment, their vibration effects, and potential external forces. Yet it has to provide, before and during the service, structural integrity.

Standards and Compliance

Regulatory compliance and industry standards essentially define the usage of aluminium profiles for electrical applications. Such standards provide assurance that the safety practices are followed uniformly in different applications, while performance standards ensure regularity. Compliance has to be periodically updated with regard to the prevailing specifications and the emerging trends in regulatory requirements.

Electrical Safety Standards

Modern electrical installations require ever-increasing safety levels to ensure proper operation and safety for users. The aluminium profiles chosen must confirm compliance with the relevant electrical safety standards, including the ability to provide grounding and proper insulation specifications. The accomplishment of these high safety standards is supported by regular testing and certification processes.

Building Codes

Construction regulations and building codes play a vital role in determining the specifications for electrical installations. The selected aluminium profiles must meet or exceed these requirements while providing necessary structural and safety features. Understanding and implementing these codes ensures both compliance and optimal performance in building applications.

Installation and Assembly Considerations

The quality of assembly and mounting of the electrical installation depends on the success of the project. The professional use of aluminium profiles requires adherence to the manufacturer’s instructions and best industry practices. Installation must be done carefully, and all of the safety measures must be applied with a comprehensive understanding and proper tools.

Mounting Systems

Contemporary aluminium profile mounting systems provide the comfort of installation with solid security options. The mounting system should ensure secure attachment with electrical isolation where required. In modern profiles, features of advanced design often lie in built-in mounting solutions that offer the whole process of connection with safety features.

Methods of connecting

The proper connecting techniques ensure both mechanical stability and electrical safety. The methods used for joining profiles and attaching electric components must be selected carefully and implemented. Modern connecting systems provide tool-less designs to facilitate quick assembly while maintaining high standards of safety. Maintenance and Long-Term Performance

Regular maintenance protocols ensure the continued safe use of aluminium profiles in electrical installations. A maintenance program should be designed with regular assessments, cleaning processes, and performance evaluation. Such practices guarantee the prevention of problems from developing into serious situations, giving a longer run on reliability.

Regular Inspection Protocols

Systematic inspection procedures ensure the safety and efficiency of aluminium profile installations in electrical applications. The assessment will include structural integrity, electrical connections, and the performance of the whole system. The documentation of such an inspection is crucial in the analysis for predictive maintenance and improvement of systems.

Preventive Maintenance

A proactive approach to maintenance maximizes the service life of aluminium profile installations while maintaining safety standards. Regular cleaning, connection tightening, and inspection of components prevent most common troubles; corrosion resistance of aluminium simplifies maintenance requirements but doesn’t eliminate the need for frequent care.

Cost considerations and value analysis

While initial investment costs are important, the total cost of ownership should guide selection decisions for aluminium profiles. Longer-term value considerations include maintenance requirements, energy efficiency, and possible upgrading capabilities. Quality materials and proper installation often lead to low lifetime costs despite greater initial expenses.

Conclusion

Careful selection of aluminium profiles for electrical safety applications means evaluating many factors. It would be a great way to base the choice of materials on their individual properties and advantages in specific situations, allowing a better choice. Technological advancements make proper profile selection even more important, so best practices and knowledge of selection criteria are increasingly valuable for professionals in related industries.