Aluminium Extrusion Suppliers: Ensuring Quality Manufacturing Success

Aluminium extrusion is a critical process of modern manufacturing using aluminium, giving versatility and durability in a wide range of industries. The demand for precision engineered aluminium profiles has been increasing exponentially, from construction to automobile manufacturing. In this article, we explore the critical contribution of aluminium extrusion suppliers and aluminium profile extrusion suppliers to the success of manufacturing operations.

1. The significance of aluminium extrusion in manufacturing

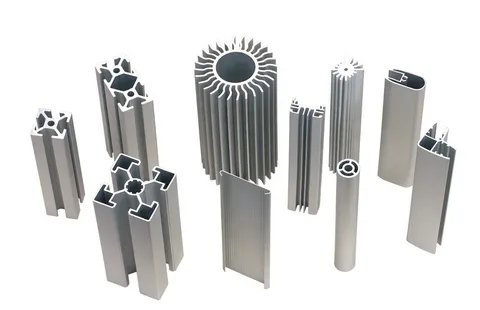

In simple terms, aluminium extrusion is the method of forcing an aluminium alloy under pressure through a die in order to obtain the determined cross-sectional shape. This form can be simple shapes like channel aluminium or complex shapes used by high-tech industries as part of their products. The benefits of aluminium extrusion are the manufacturing of components that are light, strong, and still durable.

Aluminium possesses this characteristic of corrosion resistance coupled with its lightweight and high strength-to-weight ratio, making it a very useful material in many applications. Aluminium extrusion suppliers are crucial in meeting the growing needs of various industries in sectors like aerospace, automotive, construction, and electronics. Due to this, they help in creating customized profiles with accurate details that help in the creation of efficient products to satisfy different market demands with durable quality.

2. Key considerations when choosing aluminium extrusion suppliers

There are several items that manufacturers must take into account when procuring their products from aluminium extrusion suppliers. First, a wide range of materials needs to be provided by the supplier. The strength, corrosion resistance and malleability of aluminium alloys vary greatly. Therefore, a supplier must offer several grades of aluminium, from which the manufacturers have a choice to make the most suitable alloy to meet any given specification.

The quality of the extrusion process itself is also another consideration. The die quality, extrusion machinery precision, and the care the supplier takes with the components each play a part in the performance of the end product. At all times, high-quality aluminium extrusion suppliers will keep tight tolerances and ensure that products are free of defects, such as warping and cracking.

3. Customization and flexibility in aluminium profiles

Working with aluminium profile extrusion suppliers gives you the advantage of being able to create custom profiles that are specific to your project. Aluminium extrusion customization is in the creation of a die that allows for a profile that may not be in standard catalogue offerings. This flexibility enables manufacturers to achieve more complex designs and more innovative solutions.

Often, aluminium profile extrusion suppliers can handle whether the requirement is for a certain cross-sectional shape, a certain surface finish, or a higher functionality like heat dissipation or strength. Advanced technologies such as 3D CAD and simulation software are used to deliver the final product as specified by the customer.

4. The role of technological advancements in aluminium extrusion

The aluminium extrusion industry has undergone technological advancements. Even modern extrusion machines are capable of higher precision and manufacturing more complex shapes. Staying at the forefront of these advancements is critical for aluminium extrusion suppliers to meet the increasing demands for efficiency, customization, and innovation. New possibilities for the automotive industry, construction, and many others open up due to advanced machinery capable of producing detailed profiles with tight tolerances.

They have some suppliers who invest in automated systems that enable continuous, high-volume production without sacrificing quality. The latest improvement to ensure the manufacturing process tracks and improves performance has been the introduction of AI (Artificial Intelligence) and IoT (Internet of Things). Real-time collected data can be analyzed to optimize production processes, predict future maintenance needs, and reduce downtime for the systems. The level of technological integration of aluminium extrusion suppliers enables them to optimize production schedules, reduce waste, and deliver products quicker, all while having a competitive advantage in a rapidly changing market.

5. Environmental considerations in aluminium extrusion

Modern manufacturing sets its priorities on sustainability. Aluminium is a naturally recyclable material that, as it is today, is one of the most eco-friendly materials that people use. Nevertheless, the environmental impact of this extrusion process itself, in terms of energy consumption and material waste, remains. This has led many aluminium profile extrusion suppliers to adopt more sustainable practices. They include energy-efficient extruding presses, recycled aluminium and waste reduction techniques. Suppliers can reduce their carbon footprint by optimizing production processes and minimizing energy use. Not only does it save on natural resources, but using recycled aluminium also conserves the environmental impact involved in extraction and processing. Working with environmentally conscious suppliers allows manufacturers to benefit from a reduced environmental impact and to be aligned with green standards. Not only does this cater to the growing market demand for environmentally sensitive products, but it also improves a company’s sustainability character, which, in turn, helps to bolster its marketing tactics and rate of competitive edge.

6. Importance of supplier reliability and support

Reliability is critical in the fast-paced world of manufacturing. The delays in the delivery of aluminium profiles can disrupt the production schedule, also resulting in time losses and revenue. Therefore, aluminium extrusion suppliers need to ensure that they offer consistent lead times and a reliable supply chain. A dependable supplier takes away the risk of production bottlenecks. Therefore, Businesses can manage deadlines and stay competitive.

Furthermore, customer support is a vital part of any supplier relationship. Therefore, aluminium profile extrusion suppliers should provide not only good quality products but also expertise and support for solving design challenges, increasing efficiency, or suggesting suitable materials for a certain application. To form long-term, successful partnerships, manufacturers will often choose a supplier with a good reputation for customer service. Responsive communication and technical guidance strengthen these relationships and build trust, promoting the quality of innovation and collaboration to adapt to the changes in the industry demands.

Conclusion

Aluminium extrusion suppliers and aluminium profile extrusion suppliers play an important role in the manufacturing sector. These suppliers provide high-quality, custom-engineered profiles and keep current with technological and sustainability trends to make a huge impact in countless industries. Manufacturers who want to optimize production, ensure quality and stay ahead in a constantly changing marketplace must choose the right supplier. Aluminium extrusion suppliers are essential partners in manufacturing success through reliable service, advanced technology and sustainable practices.