Benefits of Powder Coating Over Traditional Paint Finishes

When it comes to enhancing the durability and visual appeal of metal surfaces, choosing the right finish makes all the

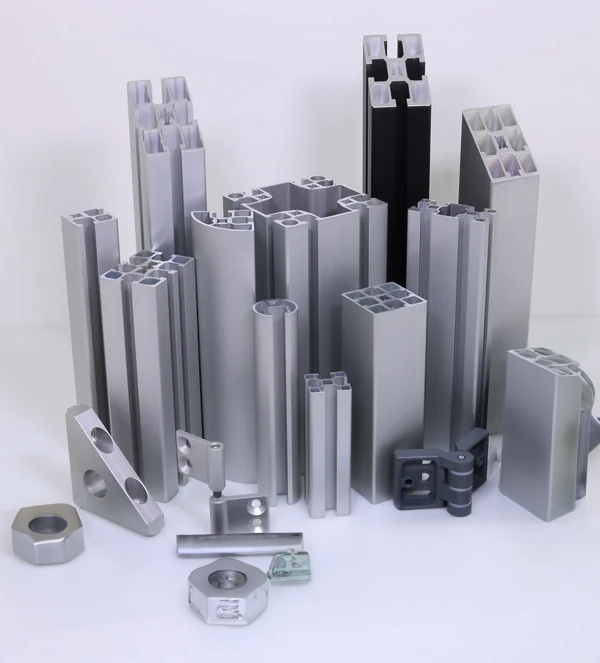

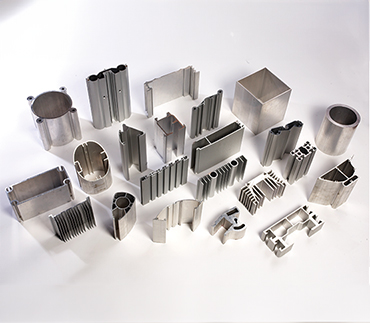

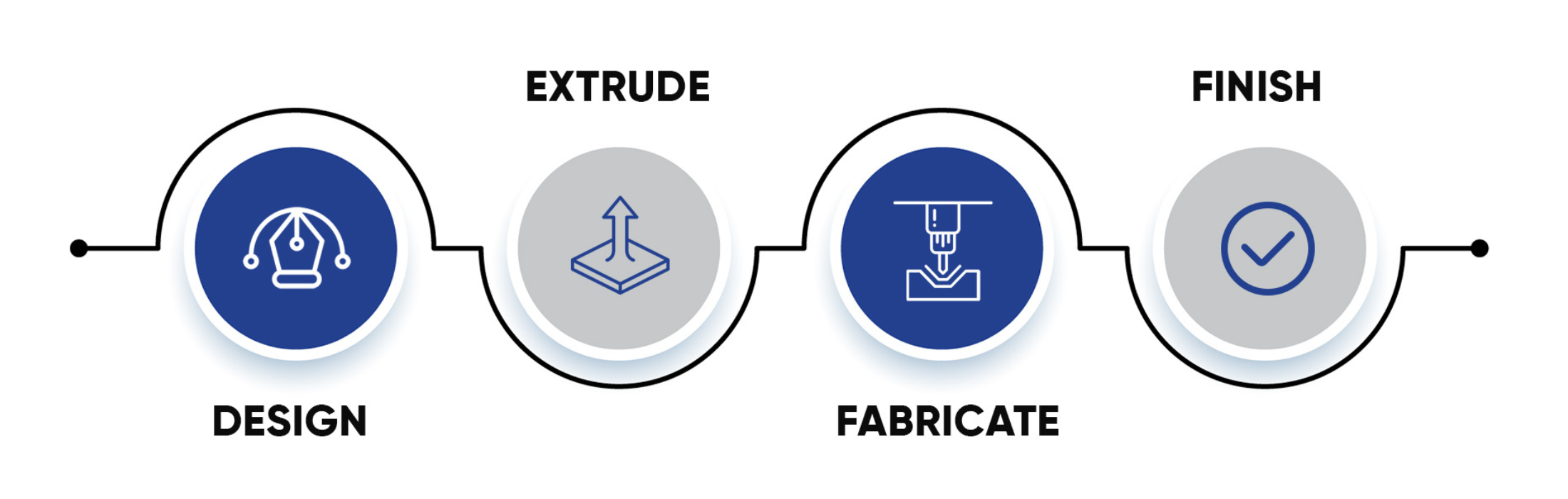

Aluminium Extrusion transforms alloys into diverse consumer and industrial products with precision and expertise.

Cost-effective and suitable powder coating methods chosen meticulously for durable and high-quality finishes.

Selecting the most suitable anodizing method for customers, ensuring cost-effectiveness and optimal results.

Precise cutting, milling, drilling, punching, and bending capabilities delivering high output with automated machinery.

Comprehensive quality control measures in place to guarantee the excellence of our products and services.

At JM Aluminum, we are committed to ensuring the highest level of quality and safety in all of our products. We use only the best materials and manufacturing techniques to ensure our products meet or exceed industry standards. Here are the things that make us competitive with other manufacturers.

We deliver anywhere. From our door to your dock, our dedicated customer service representative works directly with fleet management to provide you with quality aluminium products.

24/7 at your service. We have a team of highly skilled engineers who can assist with every stage of your project, from design to production.

We design, develop and manufacture an average of 200 dies each month through our in-house facility of 5 VMC, 1 CNC, 2 EDM, 1 Wirecut Machine

We highly value the client's design; hence, access to each project is exclusive to the teams working on it and no one else.

JM Aluminium is a leading aluminium fabrication company that offers its customers high-quality and custom-made, and standard aluminum extrusion profiles.

At JM Aluminum, we take pride in our exceptional customer service. We believe in building strong customer relationships by providing personalized service and support 24x7. Our team of engineers can answer any questions and guide the right product for your specific needs. From helping you with design, alloy choice, and surface treatment, we always work hard to provide optimized solutions. We offer fast turnaround times and on-time delivery to ensure your complete satisfaction.

Various appropriate packaging options are available at JM Aluminium, like printed/non-printed shrink tubing, interleave packing, single-piece box packing, surface protection tape, laser printing on profile, wooden box, and pallet packing. We adhere to the highest packaging standards so that the customers get the final product in pristine condition.

When it comes to enhancing the durability and visual appeal of metal surfaces, choosing the right finish makes all the

In today’s industrial and architectural landscape, material selection defines both performance and aesthetics. Aluminium extrusion profile solutions have become indispensable

Aluminium extrusions are one of the most versatile and widely used materials in modern manufacturing and construction. These profiles are

At JM Aluminum, we go beyond just providing aluminum shapes. We are your partner in creating the perfect aluminum solution. Our skilled engineers work closely with you to understand your needs and design custom extrusions that meet your exact specifications. Whether you need industrial strength or residential beauty, we have the expertise to bring your vision to life.

Our extensive selection caters to a wide range of applications. We offer everything from standard profiles like bars and tubes to complex custom designs. Need something sturdy for industrial equipment? We’ve got you covered. Building a sleek modern window frame? We can create the perfect aluminum profile for that too.

We understand that each project is unique. Our collaborative approach starts with a conversation to understand your requirements. Our engineers then translate your imagination and vision into technical drawings and guide you through the selection of the appropriate aluminum alloy. Throughout the process, we ensure clear communication and keep you informed every step of the way.

Absolutely! We offer a variety of finishing options to enhance the aesthetics and functionality of your aluminum extrusions. Our anodizing plant creates a protective and decorative layer, while our powder coating unit provides a wide range of colors and textures for a customized look.

We take pride in offering a wide range of aesthetic and functional finishes for your aluminum. Our state-of-the-art facilities allow for anodizing in natural or bright finishes, with a length of 21 feet and a thickness of 25 microns. Additionally, we have a sandblasting and polishing system to achieve a range of looks, from smooth to matte.

Yes, indeed! We understand the importance of visual appeal. Our PLC-controlled powder coating unit allows us to offer a vast array of RAL color options, ensuring a perfect match for your project’s design. We can also coat your aluminum with thicknesses up to 60 microns for long-lasting durability.

At JM Aluminum, we prioritize excellence. Our commitment to quality starts with using premium aluminum and implementing rigorous manufacturing processes. We adhere to strict quality standards, ensuring every extrusion we produce is not only beautiful but also highly durable and reliable.

We make it easy! Simply contact our team and discuss your project. Our knowledgeable representatives will answer your questions and guide you through the initial stages. We’re here to help you transform your ideas into high-quality, functional aluminum extrusions.