Top Facts about Natural Anodised Finish

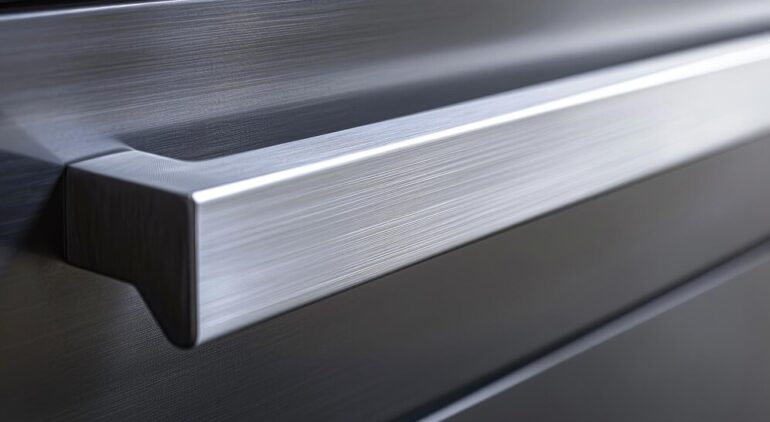

Natural anodised finishes on substrates like aluminium offer a durable and sleek surface and protection against wear and tear and corrosion. They have a refined elegance that can enhance any product, ranging from walls and windows to canopies and extrusions.

What is natural anodising?

Natural anodising is a delicate electrochemical procedure that helps convert metal surfaces into a corrosion-resistant and decorative anodic oxide finish that lasts for a long time. The amazing fact is that this finish is achieved by augmenting the natural oxide layer on the metal surfaces. Natural anodising aluminium is the most versatile treated metal in which the process causes the thickening of the natural oxide layer on its surface.

This anodising process involves dipping the aluminium into a bath of acid electrolyte and subjecting the medium to an electric current. This current leads to oxidization of the surface of anodised aluminium, forming a layer of oxide of aluminium. The point to note is that this layer is totally combined with the aluminium substrate; therefore, it will not peel or chip, offering an amazingly enduring surface that will last for many years.

Some of the benefits

As regards the scientific basis of natural anodising, it is proven that the process is a tremendous progress in the performance of the metal. The following are the main benefits of finishes of natural anodising:

Durability:

The finish of natural anodising is highly reputed for its durable and hard surface that is resistant to wear and tear and scratches. Such a finish will not chip or peel, rendering it perfect for high-traffic areas and applications. The anodised layer is attached to aluminium, ensuring a durable finish that expands the product’s longevity.

Attractiveness

Anodising offers a metallic, sleek sheen, creating a luxurious, high-end look to any product. This process permits a wide range of variants of natural colour, from rich metallic shades to deep black, without the use of paints or dyes. This helps preserve the finish of the surface for a long time and will maintain its shiny aura, improving the overall beauty of the metal.

Resistance to corrosion

A significant practical benefit of a natural anodised finish is the improved resistance to corrosion. The thick layer of metal oxide is a barrier against environmental elements that cause corrosion and rust. For instance, aluminium with an anodised finish is suited for marine applications in which the metal is subjected to salty, harsh water; this reduces the speed of corrosion and extends the usability of the metal in challenging conditions.

Guide to care for anodised aluminium metal surfaces

Aluminium and its alloys are corrosion-resistant to materials in the pH range of 5 to 8. Using abrasive materials and strong alkaline or acidic substances that contain sulphate, chloride and fluoride additives can attack and degrade the oxide layer formed by anodization. Other risk factors include a long time of contact, higher temperatures and stronger concentrations.

Following are some tips for the care of anodised metal, including black anodised aluminium extrusion:

Preventive care

A vital tip is to prevent the damage caused by corrosion from agents like contaminated plaster and cement flashes, moisture and condensates.

Aluminium surfaces must be protected from attack through:

- Delaying the installation as late as possible to minimise the potential for on-site damage.

- An ideal protective barrier must be applied before delivery to the site or much before the start of work.

It must be noted that using generic oils, lubricants, petrochemical agents, etc., is not successful in protecting against materials that can harm aluminium.

To extend the longevity of anodised metal surfaces, you must take preventive measures against abrasions and scratches. Place protective pads beneath objects that tend to move or slide, and do not place sharp materials directly upon the surface.

Immediate cleaning

Based on concentration and temperature, strongly acidic or alkaline substances can damage and leave marks on metal surfaces, such as aluminium, within minutes. Therefore, the following steps must be taken to prevent such occurrences:

- The surface must be wiped clean as soon as possible if foreign materials are accidentally splashed.

- It should be rinsed with generous quantities of clean water, particularly in crevices and cracks.

If stains and spills happen on anodised surfaces, they must be addressed urgently. Prolonged exposure to harsh materials can cause damage or discolouration. The spills must be blotted gently with a damp and soft cloth.

Regular maintenance

Similar to how you take regular care to preserve the looks of your car, it is also prudent to offer such care to maintain the decorative looks of your anodised finish.

The soil and another grime build-up will damage anodised finishes of metallic surfaces like aluminium. Such build-up can lead to corrosive conditions that can damage the coating, especially in coastal areas.

Anodic coatings must be cleaned and maintained as per a standard called AS1231-2000. The main stipulations of this standard are:

- Regular washing of finish with warm water that contains a detergent or wetting agent that is pH neutral.

- Make use of a non-abrasive sponge or brush made with fibre.

- Deep cleaning or rinsing with generous amounts of fresh water after every stage of cleaning.

Such measures must be conducted during excellent temperature conditions, especially in shade. After such cleaning, a wax polish of good quality may be used to treat the anodised aluminium. But if there is heavy soiling, more frequent cleaning is advised.

Regular cleaning is vital for not compromising the integrity and appearance of anodised surfaces. The surface can be cleaned gently using warm water and mild detergent.

How do you deal with stubborn residue?

A plastic cleaning pad like Scotch-Brite combined with water and a pH-neutral detergent may be applied to combat residue on external grade anodised surfaces. Soon after all stages of cleaning processes, clean water must be used copiously for rinsing. For this, you can even use a water jet with high pressure.

In sum, these are the main facts about natural anodising. It is applied mainly on aluminium surfaces. It offers many benefits, and the above tips for regular and periodic cleaning can help to preserve the integrity and appearance of anodised surfaces for a long time.