Sustainability in Aluminium Extrusions: Recycling and Environmental Impact

Industrial material selection and production processes underwent transformations because sustainability increased its global status. Sustainable outcomes depend strongly on standard aluminium extrusions because they provide exceptional durability and versatility together with excellent recyclability benefits. Businesses, together with their consumers, must prioritize environmental stewardship; thus, they require complete knowledge of aluminium extrusions’ sustainable characteristics for sound decision-making. A detailed article examines how aluminium extrusions impact the environment from material production through material destruction based on vital sustainability elements.

Infinite Recyclability: The Closed-Loop Advantage

Aluminium stands out among all materials because it can undergo infinite recycling cycles, which preserves its quality attributes. Today’s aluminium extrusion products have become the raw material for future products because aluminium possesses infinite recyclability properties along with minimal waste generation. During recycling processes that involve melting aluminium, neither the molecular structure nor the properties change from virgin aluminium status. This important feature saves embodied energy by significantly reducing the need to extract new raw materials. The energy needs required for aluminium extrusion recycling amount to less than 5% of initial manufacturing figures, thus promoting significant carbon reductions during each recycling process. Aluminium extrusions provide vital applications in waste reduction and resource conservation systems since these products retain their material span throughout their lifecycle indefinitely.

Energy Reduction Through Secondary Production

One of the strongest environmental justifications for recycled aluminium is the energy implications of its manufacture. A significant amount of energy from bauxite ore is required for electrolysis during the smelting process in the primary aluminium manufacturing process. However, compared to virgin manufacturing methods, the energy consumption of making aluminium extrusions from recycled material is reduced by around 95%. Reduced greenhouse gas emissions across the aluminium value chain are a direct result of this significant energy savings. Energy-efficient technology, including heat recovery systems, regenerative burners, and induction furnaces that further reduce environmental effects, are used in modern recycling operations to further this advantage. Aluminium extrusions are becoming more and more appealing due to the significant energy savings obtained through secondary production. This is because industries are looking for materials with measurable lower carbon footprints without sacrificing performance, making recycled content a crucial factor in the selection of sustainable materials.

Reduced Mining Impact: Preserving Natural Landscapes

Primary aluminium production requires bauxite mining as its first step, although this practice historically caused serious environmental damage through the destruction of habitats as well as soil degradation and tree removal. Manmade priorities between bauxite extraction and aluminium extrusions containing recycled material allow manufacturers to reduce fresh bauxite mining, which results in the preservation of sensitive biodiversity-rich natural ecosystems. Miners can protect over four tons of bauxite resources by recycling one ton of aluminium, thus saving environmentally critical biodiversity areas for carbon storage. Environmentally responsible practices should focus on recycling instead of extraction because mining progress has not changed this basic principle.

Transportation Efficiency: The Lightweight Advantage

The strong strength-to-weight relationship of aluminium extrusions creates substantial weight savings for transportation needs that, in turn, produce major sustainability advantages. When automotive and aerospace industries utilize aluminium instead of heavier materials for every kilogram the resulting savings produce reduced fuel consumption, and emission decreases throughout vehicle operation. Environmental advantages from fuel economy enhancements total twice as much as the manufacturing impact due to weight reductions of 10%, which result in a 6-8% rise in fuel economy, scientific studies show. Beyond the actual transportation items, aluminium extrusions’ lightweight design lowers shipping energy needs throughout distribution since they allow for the carriage of more components per shipment than heavier alternatives. Because lighter components take less energy to install and allow for reduced foundation requirements, this transportation efficiency also applies to building applications. Aluminium extrusions are especially useful in applications where lifetime energy usage surpasses manufacturing considerations due to the combined effect of these weight benefits.

Design for Disassembly: Facilitating Material Recovery

Aluminium extrusions’ intrinsic qualities perfectly fit design-for-disassembly guidelines, which makes it easier to recover materials at the end of their useful lives. Aluminium extrusions usually join using mechanical fastening techniques that enable simple separation during decommissioning or renovation procedures, in contrast to composite materials that mix components inseparably. When compared to permanently bonded assemblies that need energy-intensive separation processes, this separability significantly increases recycling rates. In order to improve future recyclability, forward-thinking manufacturers are increasingly using snap-fit connectors, reversible adhesives, and standardized component specifications. Eddy’s current separation method effectively separates aluminium from mixed waste streams, making automated sorting in material recovery operations much easier due to aluminium’s non-magnetic nature. In order to achieve circular material flows that optimize aluminium’s sustainability potential over several product lifecycles with little downcycling or material loss, some design considerations are essential.

Extended Service Life: Durability as Sustainability

Aluminium extrusions’ remarkable endurance, which distributes the environmental effect across decades of practical usage, is a commonly disregarded sustainability feature. Aluminium extrusions’ intrinsic resistance to corrosion, structural stability, and dimensional correctness let them last for more than 50 years in construction applications without experiencing any performance deterioration. Compared to less durable options that need to be replaced on a regular basis, this increased durability immediately lowers replacement frequency and related resource usage. Aluminium extrusions that are correctly finished by anodizing or powder coating require little upkeep to retain their functioning and beauty. This improves their sustainability credentials by removing the need for chemical treatments and refinishing procedures while in use.

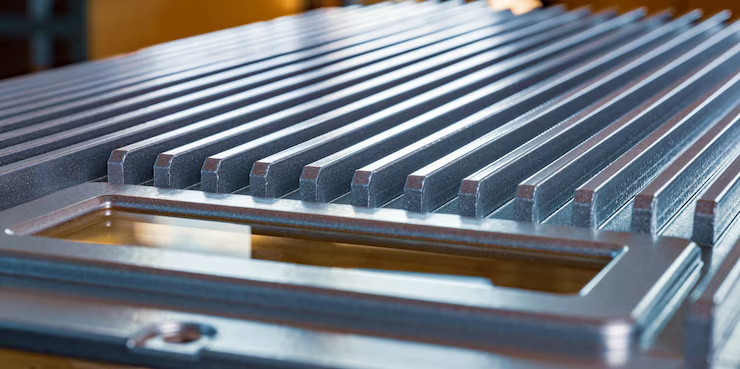

Material Efficiency: Optimizing Resource Utilization

Through precise shaping that reduces waste production, the extrusion manufacturing process provides impressive material efficiency gains. Compared to conventional machining techniques, computer-optimized die designs greatly reduce material removal by producing near-net-shape profiles that require little further processing. Extrusion’s controlled deformation preserves uniform material qualities across intricate geometries, allowing for structural optimization that lowers material needs without sacrificing performance attributes. Closed-loop scrap recycling, in which residues are processed instantly to rejoin the material stream without leaving the plant, is another way that modern industrial methods improve resource efficiency. Hollow sections and internal reinforcing elements that optimize strength while reducing material mass are made possible by the design flexibility of extrusions.

Conclusion

The Aluminium Extrusion Manufacturer in India sustainability profile illustrates why this adaptable material is becoming more and more popular in ecologically friendly building and design. Aluminium extrusions provide strong benefits throughout the course of their whole lifespan, from their unmatched recyclability to their advantages in operating efficiency. The eight factors that were looked at demonstrate how aluminium extrusions support sustainability through lower energy use, less resource extraction, more efficient transportation, flexible design, and remarkable endurance. These traits are ideal for the circular economy, which emphasizes resource optimization and material recirculation.