Innovations in Electrical Aluminium Profiles: Shaping the Future of Energy Systems

Profiles of aluminium have been used as long-standing features across numerous sectors, including electrical systems. They are lightweight, durable, and resistant to corrosion, and they are the best materials for the components manufactured for energy systems. Lately, the need for advanced engineers in electrical aluminium profiles has increased because the development of modern energy systems that are considered sustainable, efficient, and high-energy-demanding systems has come up with new challenges. Several current trends in electrical aluminium profiles redefine energy systems in the article.

Significance of Electrical Aluminium Profiles in Present Day Energy Systems

Due to aluminium’s high conductivity, strength-to-weight ratio, and resistance to the environment, it is used in energy systems such as renewable infrastructure, power distribution, and transmission lines as electrical aluminium profiles. These systems have a growing need for sophisticated aluminium profiles, and they have spurred innovations that help maintain these systems in an efficient, safe, and sustainable manner.

- Lightweight and High-Strength Aluminium Alloys

The lightweight revolution supported by high-strength aluminium windows made advancements in engineering significantly extends aluminium profiles. These alloys have the weight advantage of aluminium but are incredibly strong, particularly in instances such as power line support, where the power lines must span great distances. The better the strength-to-weight ratio, the less weight is applied to the carrying structure, which helps to save energy in long-distance transmission as less energy loss occurs; hence, such alloys find application in modern power systems where efficiency is critical.

- Advanced Surface Coatings for Durability

Surface finishing techniques such as anodising, powder coating, or even electrophoretic deposition (EPD) have changed the game for many aluminium extrusions as these processes can now make the products more resistant to corrosion, UV light and extreme weather conditions as well. Such coatings also prolong the service life of the structural assemblages made of aluminium designed for energy systems, such as solar or wind energy systems placed in the ocean, which limits the exposure to the effects of weather corrosion. This allows for maintaining the operational characteristics of aluminium profiles, thus avoiding excessive expenditure on repairs and increasing the durability of energy infrastructural systems.

- Smart Aluminium Profiles for Energy-Efficient Management

The use of smart profile systems in aluminium profiles has equipped energy systems with monitoring functions that operate in real time. Profile systems that contain sensors can measure and monitor temperature, voltage, and current, and this information can be used to recognise a problem before an energy system fails to operate as required. This allows the development and enhancement of smart grids aimed at efficient use of the energy produced by the electric power plants through the distribution networks, maintenance of low power losses to the consumer, and performance of maintenance on the systems ahead of time. Thus more efficient and less costly energy provision systems are achieved.

- Aluminium Profiles for Renewable Energy Systems

Due to their low weight and high resistance to corrosion, the aluminium profiles are very important in renewable energy systems, especially in solar and wind energy systems. In solar panels, the aluminium frames are used to support the solar panel and are meant to withstand any harsh weather conditions, while in the case of wind turbines, which use aluminium, less weight translates to less mechanical stress and, therefore, more efficiency. These technological advancements guarantee that aluminium sections in renewable energy solutions are long-lasting, qualitatively inexpensive, and function effectively over a long time, thus supporting the energy industry’s economy.

- Sustainability and Recyclability of Aluminium Profiles

Aluminium is one of the most sustainable materials, and the fact that it can be completely recycled minimises the energy systems’ environmental footprints. Improved recycling achieved in other energy facilities makes it practical to refabricate expired aluminium sections from vertical energy systems at the expense of cutting down resources and energy. In addition, aluminium production is becoming greener since many manufacturers are already incorporating green energy in their processes, thus making aluminium more favourable to modern energy systems.

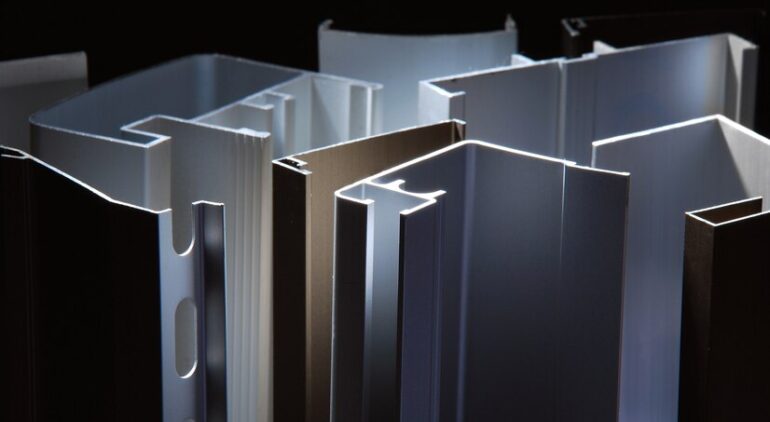

Classes of Aluminium profiles

The aluminium profile has many classes tailored towards different functions, with some offering advantages over others in terms of strength, flexibility, durability and aesthetics. The most known types of aluminium profiles include:

- Structural Profiles: These are multipurpose and commonly used in the built environment and other engineering fields, offering strong and resilient frameworks for structures such as buildings, bridges, and machinery. They are available in basic forms of I-section beams, U-section channels, corner sections, and T-section profiles.

- Extruded Profiles: These are formed of aluminium shapes created by extrusion and are structurally along thin-walled sections that perform distinct purposes, making them suitable for architectural, transport, and electrical fittings and generally known as a section.

- Heat Sink Profiles: Heat sink profiles are designed to transfer heat away from heat-generating components and are utilised in cooling equipment such as computers, LED lighting, and power electronics. These profiles are usually provided with fins or furnace-like ridges that help to improve heat transfer by enlarging the heat transfer surface.

- Framing Profiles – More about framing profiles that are used, especially in modular systems and assembly lines, to create structures for machines, furniture, display systems, etc. These profiles are easily adjustable and are quite simple to put together and change arrangement or configuration.

- Round and Square Tubing Profiles – These profile systems are most commonly used in any construction that will require a well-defined shape and strength, such as furniture, torsion boxes, railings, infrastructural trusses, etc. They provide rigidity and are widely used because of their attractive appearance and simplicity of fitting.

To wind up, aluminium profiles are highly needed in contemporary energy systems. They are lightweight, long-lasting, and can withstand detrimental elements. Advanced alloys, coatings and smart technologies are facilitating their applications in renewable energy and power transmission. Considering their sustainability and recyclable value, aluminium profiles are instrumental in providing an effective energy system, thus making it impossible to do away with them in the energy systems of tomorrow.