With the growth and diversification of Indian industries, the requirement of extruded aluminium products in the country has also increased tremendously. Whether it is construction, automobiles, aviation, or any other field that demands highly accurate aluminium components, the choice of the supplier matters. The following are guidelines that can help one distinguish the best aluminium extrusion manufacturers in India based on quality and innovative features. We will discuss some of the factors, such as the location of extrusion manufacturers. For example, most of the aluminium products manufacturers are located in Pune, and how to study aluminium product manufacturers across India.

Why Quality and Innovation Are Valuable

That being the case, let us briefly delve into why quality and innovation cannot be overstressed enough when searching for an aluminium extrusion manufacturer. Quality focuses on reliability, durability, and performance, while the idea of innovation is about efficiency, low cost, and competitiveness. By so doing, you will be able to position your endeavours in the most appropriate position to get the best industry offers.

Tip 1: Industry Reputation and Track Record

Begin your search by looking into some aluminium product manufacturers in India and their standing. Find firms that have produced outstanding products and services and continually present new ideas to the marketplace. Current customer opinions, trade journals, and professional organisations are some of the avenues that can help one determine the reputation of a manufacturer. Convey concern about their tenancy and their evolution process, and these will let you know if they are stable and if they are a successful company.

Tip 2: Consider Technical Strengths and Tools

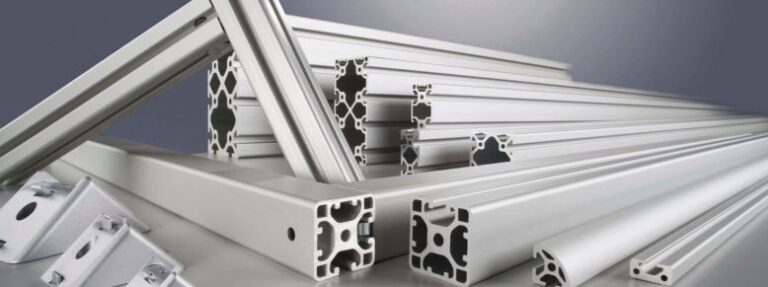

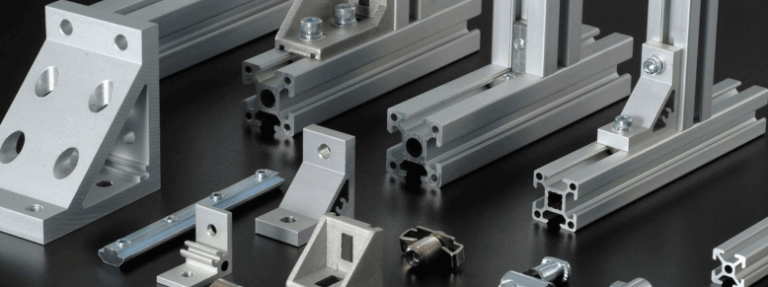

Leading producers of aluminium extrusions incorporate a number of production technologies into their operations. All sanctions are encouraged to ask questions regarding their production capacity when manufacturing profiles, the type of extrusion press they use, the capacity, and the types of profiles they can manufacture. Higher sophistication of the equipment means that there can be enhanced precision, good quality, and capacity to deal with more intricate designs.

Tip 3: Assess Quality Control Measures

Quality control is a critical aspect of aluminium extrusion manufacturing. Look for manufacturers that have robust quality management systems in place. ISO certifications, such as ISO 9001, are good indicators of a company’s commitment to quality. Ask about their quality control processes, including material testing, in-process inspections, and final product verification. The best manufacturers will have comprehensive quality assurance programs that ensure consistency across all their products.

Tip 4: Consider Location and Logistics

The location of the manufacturer can play a significant role in your decision-making process. For instance, Pune has a notable concentration of aluminium extrusion manufacturers, making it a hub for this industry. Choosing a manufacturer in a strategic location can offer advantages in terms of logistics, lead times, and potential cost savings. However, don’t limit your search geographically if a manufacturer outside your immediate area offers superior quality or innovation.

Tip 5: Look for customisation capabilities.

The ability to produce custom extrusions is a hallmark of top aluminium product manufacturers. Evaluate potential partners based on their willingness and ability to work on custom designs. This flexibility is crucial if you have specific requirements for your projects. Ask about their design support services, prototyping capabilities, and experience in developing unique solutions for clients in various industries.

Tip 6: Examine Their Range of Products and Services

Leading aluminium extrusion manufacturers often offer a wide range of products and value-added services. This diversity can be beneficial if you have varying needs or if your requirements might change in the future. Look for manufacturers that provide not just extrusion services but also additional processes like fabrication, surface finishing, and assembly. A one-stop shop can streamline your supply chain and ensure consistency across all your aluminium components.

Tip 7: Assess Their Commitment to Innovation

Innovation is key to staying competitive in the aluminium extrusion industry. Investigate how potential manufacturers approach research and development. Do they regularly introduce new alloys, extrusion techniques, or finishing processes? Are they investing in technologies to improve efficiency and reduce environmental impact? A manufacturer’s commitment to innovation can directly impact the quality and competitiveness of your final products.

Tip 8: Check for industry-specific expertise

Different industries have unique requirements for aluminium extrusions. Whether you’re in automotive, construction, or electronics, looks for manufacturers with specific experience in your sector. This expertise ensures that they understand the regulatory requirements, performance standards, and unique challenges of your industry. Aluminium extrusion manufacturers in Pune, for example, may have particular strengths in certain sectors due to the industrial ecosystem in the region.

Tip 9: Evaluate Sustainability Practices

In today’s environmentally conscious market, the sustainability practices of aluminium product manufacturers are increasingly important. Look for companies that prioritise energy efficiency, waste reduction, and recycling in their operations. Sustainable practices not only benefit the environment but can also lead to cost savings and improved product quality. Ask about their use of recycled aluminium, energy-efficient equipment, and any certifications related to environmental management.

Tip 10: Consider financial stability and capacity

The financial health of a manufacturer is crucial for ensuring a stable and long-term partnership. While it may be challenging to access detailed financial information, you can look for indicators of financial stability such as consistent growth, investment in new equipment, and expansion of facilities. Additionally, consider their production capacity to ensure they can meet your current and future needs without compromising on quality or lead times.

Conclusion

Finding top aluminium extrusion manufacturers in India requires careful consideration of multiple factors. By focusing on quality, innovation, technical capabilities, and industry expertise, you can identify partners that will contribute to the success of your projects. Remember to look beyond just the product specifications and consider the overall value proposition, including location advantages, such as the concentration of aluminium extrusion manufacturers in Pune, sustainability practices, and customer support.

The landscape of aluminium product manufacturing in India is dynamic and competitive. By applying these tips and conducting thorough research, you can forge partnerships with manufacturers that not only meet your current needs but also support your growth and innovation in the future.