Have you ever been inspired to create a new design or product but found it difficult to make it happen? While originality is vital, the correct equipment and supplies are needed to translate ideas into physical works of art. When attempting to bring their ideas to life, designers, along with engineers as well as makers, can find a flexible solution in aluminium profiles. Aluminium is a versatile, strong, and lightweight material that can be used for a variety of purposes. Custom aluminium profiles can be used to transform ideas into working prototypes, goods, and constructions. This post will examine how ideas can be realized from conception to completion with the aid of Customised Aluminium Profiles.

- Design Flexibility

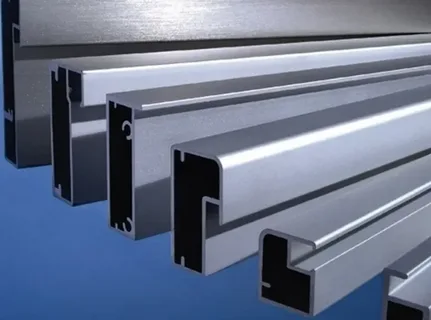

The great degree of flexibility offered by aluminium profiles makes them an excellent choice for design and production. Aluminium is a material that can be extruded into a wide range of profiles and shapes with different dimensions. Basic extruded sections like rectangular, circular, I-beams, and T-slots are examples of common profile types. Aluminium profiles, however, come in a variety of shapes and sizes. Their measurements can be greatly altered to accommodate almost any kind of design requirement. Profiles come in a broad variety of thicknesses, ranging from less than 1 mm to several inches. They differ in length as well. Designers are able to precisely specify the size, thickness, and geometry needed for their projects thanks to this high degree of dimensional customization.

Aluminium extrusions can be further machined, bent, welded, or combined in various ways to create highly complex assemblies and structures in addition to standard profile types. Aluminium profiles can be used to create nearly any complex geometric shape or component using methods like CNC machining. Iterative prototyping techniques are also supported by their modular design. Designers have almost endless freedom to physically realize even the most complex design concepts and innovations because of the flexibility of aluminium profiles. With the help of additional machining, modular profile assembly, and customized dimensions, the material can be shaped into any desired shape or configuration. Because of this, aluminium profiles are especially suited to bringing conceptual concepts to life in the form of functional prototypes, buildings, and products.

- Rapid Prototyping

The ability to swiftly create physical prototypes of a design from digital files, such as CAD (computer-aided design) models, is known as rapid prototyping. This is an essential phase in the creation of new products because it enables engineers and designers to test their concepts in the real world before investing a large amount of time and money. Because of some of the material’s intrinsic properties and processing capabilities, custom aluminium profiles allow for extremely efficient rapid prototyping. First off, with simple machinery, aluminium extrusions can be easily and precisely cut to the desired lengths. Standard profile stock lengths are between one and six meters, which minimizes material waste. You can also order non-standard lengths. Second, CNC (computer numerical control) machinery can be used to machine aluminium profiles using a computer.

This enables the on-site production of complex geometric features, such as holes, slots, and surfaces, straight from CAD drawings in a workshop setting. In prototype parts and assemblies, CNC machining provides profiles with a very high degree of dimensional accuracy and repeatability. With the help of CNC machining and readily available standard or custom profile lengths, physical prototypes can be manufactured very quickly—possibly in a matter of days or weeks after a digital design is finalized. Compared to options that need substantial manual tooling or casting, this is substantially faster.

- Versatile Applications

Because of their strength, low weight, and adaptability, aluminium profiles are used in many different industries and applications. They function as strong yet lightweight structural components for machinery, equipment, cars, and other things in engineering. Profiles are used in the construction industry for flooring, formwork, scaffolding, and other purposes. Exhibition designers make use of their aesthetic versatility and modularity when creating environments and displays for trade shows. Makers use profiles as the building blocks for a wide range of do-it-yourself projects, ranging from robots to furniture. Custom profiles are used by the education sector to build models and prototypes of inventions. They are also ideal for use in harsh environments such as transportation, the marine industry, and others due to their resistance to corrosion. Aluminium profiles offer a solution that makes even the most abstract ideas a reality, whether they are artistic or industrial in nature.

- Ease of Assembly

Aluminium profiles are incredibly simple to work with and assemble, even though they offer a great deal of design flexibility. Bolting, screwing, clamping, and welding are common joining techniques that enable reversible and non-permanent connections. To make joining parts easier, many profiles have T-slot grooves or pre-drilled holes. Even complicated assemblies can be put together in a few hours or days with the correct tools. Because of their low weight, entire structures can frequently be assembled and managed by just one or two persons. It’s critical to reduce assembly time and effort from the beginning of prototyping to the end of production. The entire process, from conception to completion, is streamlined by the simplicity with which custom aluminium profiles can be assembled.

- Cost Effectiveness

Apart from their practical benefits, customized aluminium profiles also offer an affordable option. Although there may be initial setup costs associated with purchasing tools, producing profiles in large quantities is an effective industrial process. Because of this, even custom sizes are frequently more affordable than alternative materials. Because of its lightweight, aluminium is also more affordable in the long run than alternatives like steel because it requires less material to achieve the same strength and lowers shipping costs. It is also possible to recycle any waste that results from cutting profiles to length. When compared to alternatives that need to be replaced frequently, products and structures made of aluminium profiles have a longer service life and lower life-cycle costs. Whether used to create display units, prototypes, or final goods, custom profiles offer excellent performance at a reasonable cost.

Conclusion

Tailored aluminium extrusion profiles are a flexible material that can bring ideas from the mind to the real world. Their versatility, ease of assembly, quick prototyping, and a broad range of applications enable designers to overcome obstacles at every stage of the product development process. Aluminium profiles facilitate the process of taking an idea from the drawing board to a finished product by streamlining iterative prototyping as well as refinement, mass production, and final sketching and modelling.