Aluminium anodizing is a frequently utilized technique to improve aluminium’s innate qualities, giving it increased strength, resistance to corrosion and good looks. This paper brings out numerous positive sides of the process of aluminium anodizing, pointing out why there should be an aluminium anodizing plant and where we can use aluminium profiles after they have been anodized.

Enhanced durability and resistance

The major advantage of aluminium anodizing is improved durability and resistance against corrosion. In other words, when raw aluminium reacts chemically with oxygen through a certain process called oxidation (anodic), it creates an oxide film on its surface, hence increasing its capacity to become stronger. It’s this harder oxide layer that resists wear and tear compared to soft-natured natural aluminium that wears out easily due to friction.

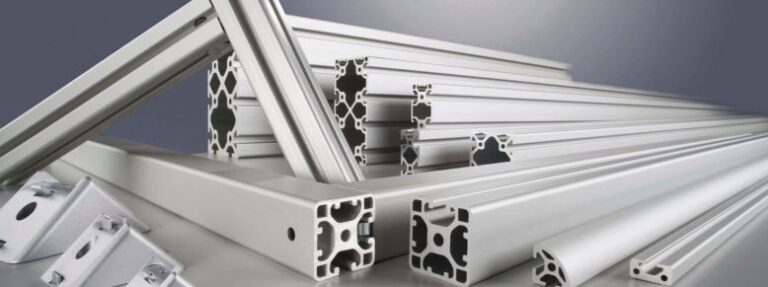

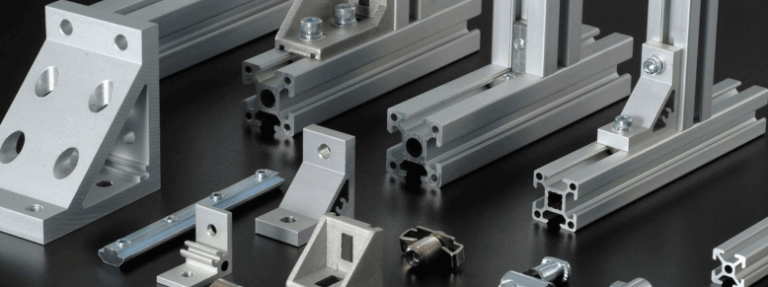

An anodic oxidized aluminium profile has extremely high resistance against corrosion, thus being useful for areas exposed to harsh weather conditions. The moisture barrier formed by the oxide layer stops water and other corrosive substances from entering the aluminium while at the same time prolonging its life span. Thus, ‘anodized’ aluminium has become widely used in outdoor structures such as bridges or towers, marine craft or along sea lines, and industrial structures, amongst others.

Aesthetic versatility and customization

Aluminium anodizing offers many aesthetic choices so that it can be customized to meet the needs of specific designs. Anodizing also has varying finishes and colours, ranging from rough to smooth, for users who want to achieve an architectural and decorative look.

When it comes to anodizing, one of the significant benefits is the power to colour the oxide layer in several different hues. This quality is especially important within the automobile and consumer electronics sectors, where aesthetics play a key role. On the other hand, the aluminium anodizing plant can adapt its process of anodizing to obtain uniform and consistent colours, which means that the products’ appearances are improved by high-quality finishes. Additionally, besides its visual attraction, anodized aluminium is more resistant to corrosion and wear than non-anodized aluminium, thus making it ideal for functional or decorative purposes in various industries.

Enhanced surface hardness and scratch resistance

Anodizing substantially increases the surface hardness of aluminium, making it resistant to scratches or mechanical damage. The oxide layer developed through anodization is far harder than the base aluminium hence giving a long-wearing surface withstanding heavy use as well as abrasion.

Enhanced toughness is especially advantageous for instances where aluminium surfaces are frequently touched or moved, such as in the building industry where anodized Aluminium profiles are used in window frames, door frames and facades that must maintain their appearance under harsh conditions and physical abuse.

Improved thermal insulation and reflectivity

Anodized aluminium is an effective material for applications requiring temperature regulation because it has enhanced thermal insulation properties. Heat dissipation through the aluminium surface is improved by increasing the emissivity of the surface through the anodization process. Therefore, it is important to make heat sinks and other thermal management components.

Apart from that, this type of aluminium is anodized to achieve a higher reflectivity and can be used in lighting systems and solar energy. These reflective properties help maximize the output of light, hence increasing solar panels’ efficiency. Accordingly, anodized aluminium profiles are critical to sustainable energy solutions while enhancing solar power systems for better results. Together with improved thermal management and greater reflectivity, anodized aluminium becomes a valuable material for industries involved in energy conservation and furthering sustainability objectives. Better performance can be realized by including anodized aluminium in these applications, thus facilitating greener technology development by manufacturers.

Environmentally friendly and sustainable

Aluminium Anodising is an environmentally friendly method aligned with sustainable manufacturing practices. The anodizing process does not require dangerous chemicals, and this oxide layer is harmless and safe for the environment. The most important thing is that anodized aluminium can be recycled entirely, leading to waste minimization and the conservation of natural resources.

Some environmentally friendly practices in an Aluminium Anodizing plant may include minimal waste generation during the process and energy-efficient techniques. Also, anodized aluminium is sustainable, and as such, it can be used in green buildings and making eco-friendly products. Furthermore, durability is responsible for extending the life of products, thereby minimizing periodic replacements, hence reducing overall environmental impact. Manufacturers and consumers who choose anodized aluminium for product designs can contribute towards a more sustainable future by embracing a versatile material that is also durable enough besides being environmentally friendly. This corresponds with sustainability trends around the globe, which emphasize responsible production practices.

Cost-effective and low-maintenance

Aluminium Anodizing provides cost-effective solutions for many applications because it has long-lived performance characteristics with little upkeep needed. Anodized aluminium’s durability and corrosion resistance make it unnecessary to replace or repair as often, which implies significant long-term savings.

However, unlike painted or coated surfaces, anodized finishes do not peel, chip or flake off; hence, they retain consistently high quality and require less maintenance. Consequently, it is suitable for use in applications where long-term dependability and cost-effectiveness are essential. For instance, industries such as construction, transportation, and consumer goods enjoy lower life cycle costs due to aluminium anodizing, thus making it more practical for both large-scale and everyday applications. Moreover, its resilience to environmental factors like UV radiation and pollution increases its worthiness even further, which allows the use of it as a practical, economically sound material.

Conclusion

To sum up, aluminium anodizing has multiple advantages that come along with it, enhancing the properties of aluminium. Applications such as the construction and automotive sectors, the electronics industry, and renewable energy, among others find anodized aluminium suitable due to its improved toughness, corrosion resistance and flexibility in terms of aesthetics.

The presence of the aluminium anodizing plant guarantees a high-quality anodized aluminium profile that meets specific design and performance criteria. Also, surface hardness improves heat insulation properties and is environmentally friendly, making this material very attractive for many industries.

Anodized aluminium offers manufacturers and designers durable, aesthetically appealing, economical alternatives that can stand up to the test of time. This shows that continuous improvements are taking place in aluminium anodizing technology, which indicates even greater developments in the future, thus broadening the horizons of this adaptable substance.